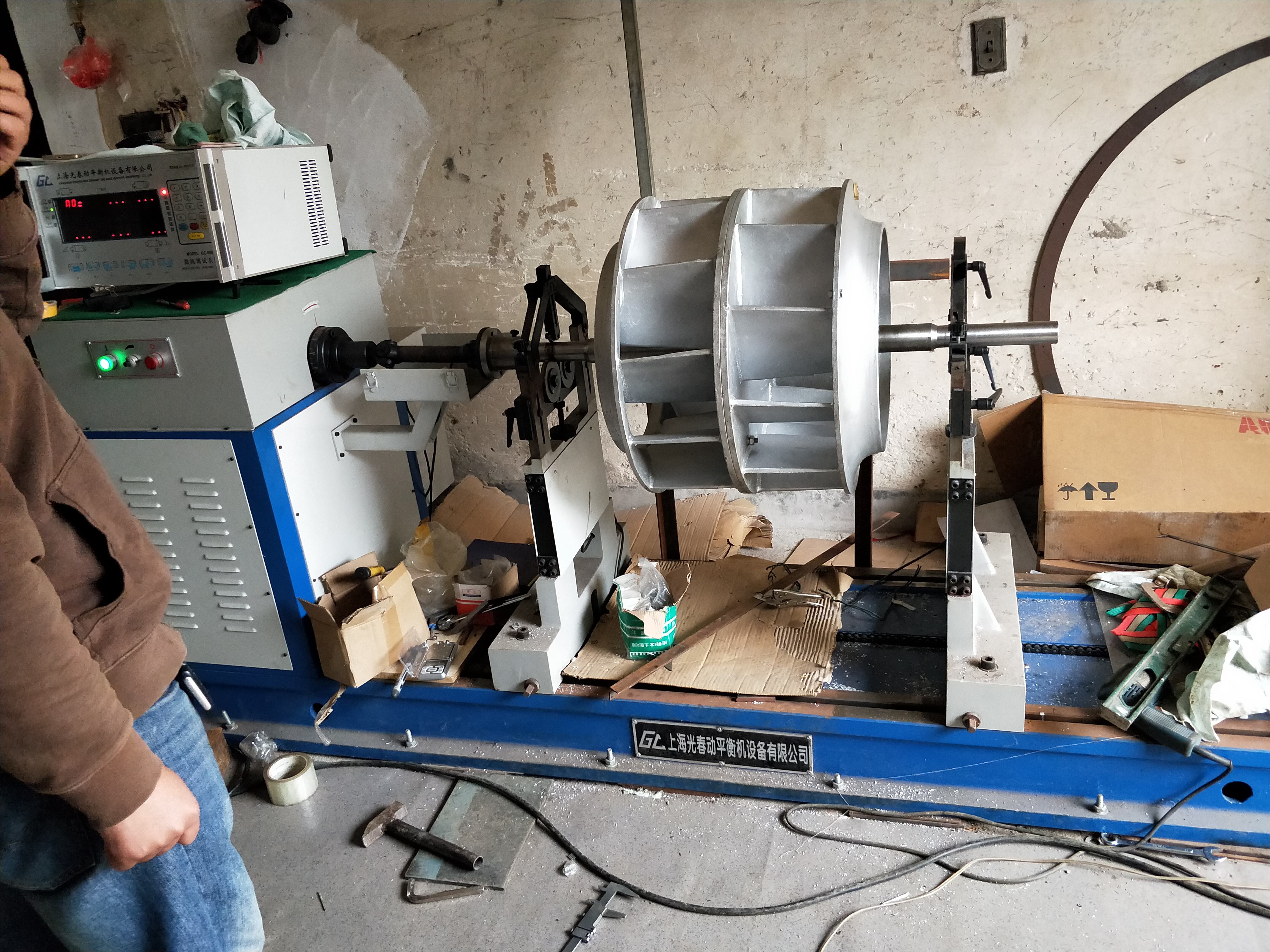

crankshaft balancing for diesel engines

Crankshaft balancing for diesel engines is a critical mechanical process that ensures optimal engine performance and longevity. This precision-oriented procedure involves equalizing the weight distribution around the rotating axis of the crankshaft, effectively minimizing vibration and stress during engine operation. The process employs sophisticated electronic equipment to measure and correct both static and dynamic imbalances, ensuring that the crankshaft rotates smoothly at all engine speeds. Modern balancing techniques utilize computer-aided measurements to detect even minimal irregularities, typically measured in gram-inches, which could potentially cause harmful vibrations. The procedure involves adding or removing material from specific locations on the crankshaft to achieve perfect rotational balance. This technical process is essential for maintaining engine efficiency, reducing wear on bearings and other components, and ensuring smooth power delivery. Professional balancing services typically include comprehensive inspection of the crankshaft, precision measurement of journal roundness, and careful attention to weight distribution across all rotating masses, including the flywheel and harmonic balancer.