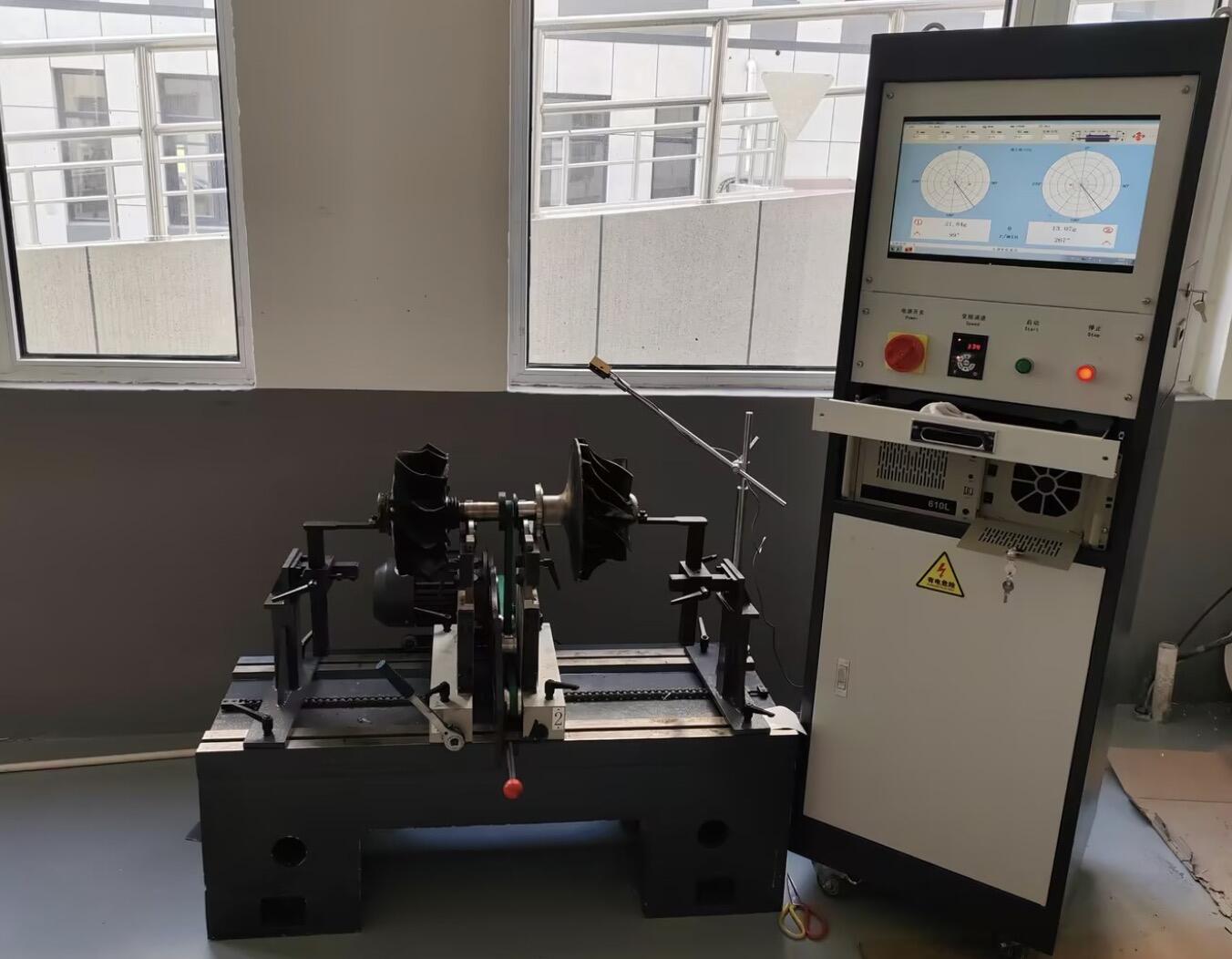

turbo balancing machine for sale

The turbo balancing machine represents a cutting-edge solution for precision balancing of turbine components, incorporating advanced digital technology and robust mechanical engineering. This state-of-the-art equipment utilizes high-sensitivity sensors and sophisticated software algorithms to detect and correct imbalances in turbochargers, turbine rotors, and other high-speed rotating components. The machine operates through a combination of real-time measurement systems and automated correction processes, ensuring accuracy down to microscopic levels. It features a user-friendly interface that guides operators through the balancing process, from initial measurements to final verification. The system accommodates various component sizes and weights, making it versatile for different industrial applications. With its precision measuring capabilities, the machine can identify imbalances as small as 0.01 gram-millimeters, ensuring optimal performance of balanced components. The integrated safety features, including automatic emergency stops and protective enclosures, guarantee operator safety during the balancing process. This machine proves essential for automotive manufacturers, aerospace industries, and general manufacturing facilities where precision balancing is crucial for product quality and reliability.