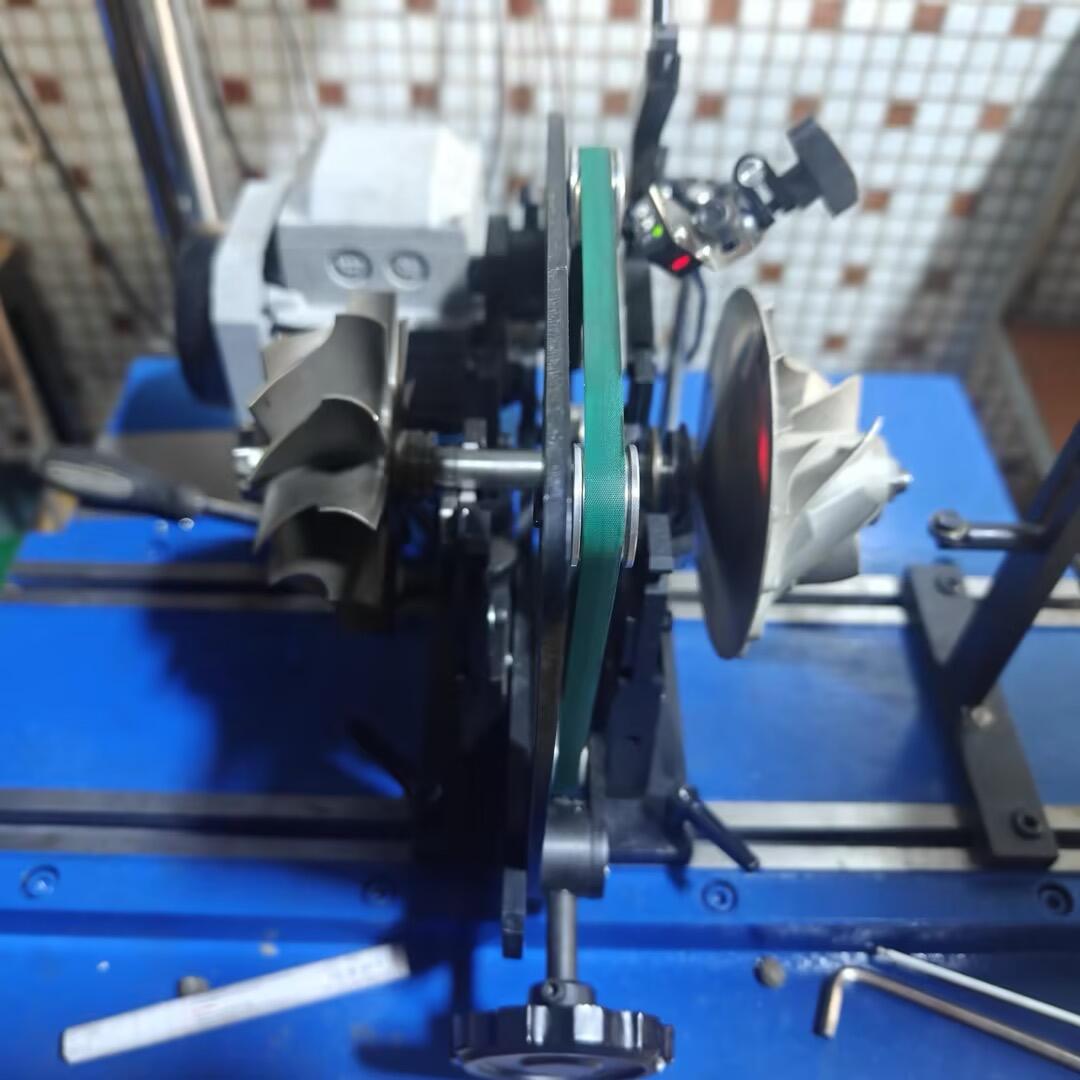

aerospace turbine balancing equipment

Aerospace turbine balancing equipment represents a critical technological advancement in aviation maintenance and safety. This sophisticated machinery is designed to ensure optimal performance of aircraft engines by precisely measuring and correcting rotational imbalances in turbine components. The equipment utilizes state-of-the-art sensors and digital analysis systems to detect even minute vibrations that could compromise engine efficiency and safety. The primary function involves high-precision measurements of weight distribution across turbine blades and rotors, allowing technicians to make necessary adjustments to achieve perfect balance. Modern aerospace turbine balancing equipment incorporates advanced features such as real-time data analysis, automated calibration systems, and comprehensive diagnostic capabilities. These systems can operate across a wide range of rotational speeds and can handle various turbine sizes, from small private aircraft engines to large commercial jet turbines. The equipment's applications extend beyond routine maintenance to include quality control in manufacturing, performance optimization, and troubleshooting of vibration-related issues. With integrated computer systems and specialized software, these machines can generate detailed reports and maintain historical data for trend analysis and predictive maintenance.