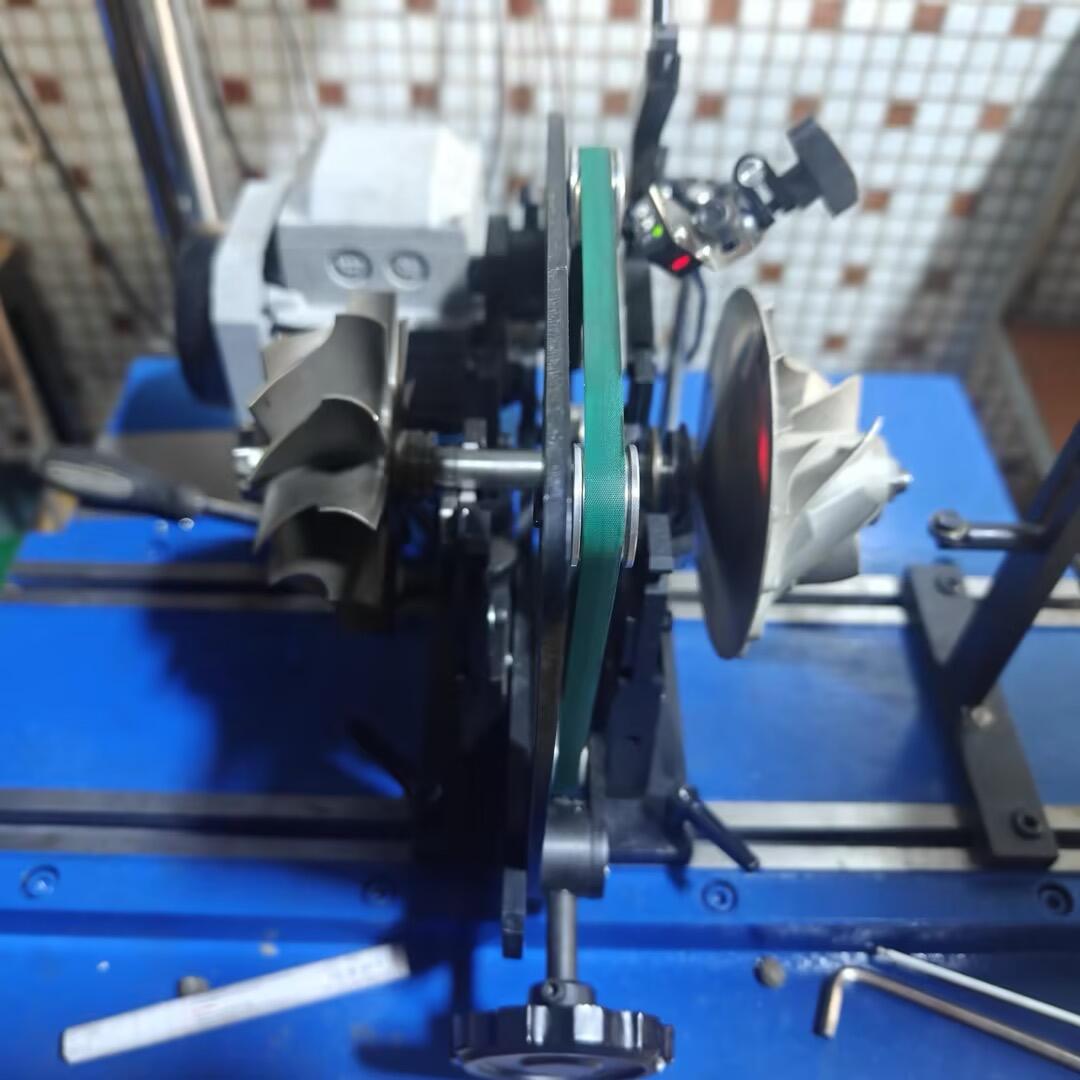

turbine balancing machine

A turbine balancing machine is a sophisticated piece of equipment designed to ensure the optimal performance and longevity of rotating machinery. This precision instrument measures and corrects imbalances in turbine components, including rotors, impellers, and shafts. The machine operates by spinning the component at specific speeds while utilizing advanced sensors to detect any irregularities in the rotation pattern. These sensors measure vibration levels and pinpoint exact locations where weight needs to be added or removed to achieve perfect balance. Modern turbine balancing machines incorporate computer-controlled systems that provide real-time data analysis and automated correction recommendations. They can handle components ranging from small precision parts to massive industrial turbine rotors weighing several tons. The technology employs both horizontal and vertical balancing capabilities, allowing for comprehensive testing across multiple planes. These machines are essential in various industries, including power generation, aerospace, automotive manufacturing, and industrial processing. They ensure that turbines operate at peak efficiency, minimize wear on bearings and other components, and reduce energy consumption. The precision of modern balancing machines can detect imbalances as small as a fraction of a gram, making them invaluable tools in maintaining the highest standards of equipment performance and reliability.