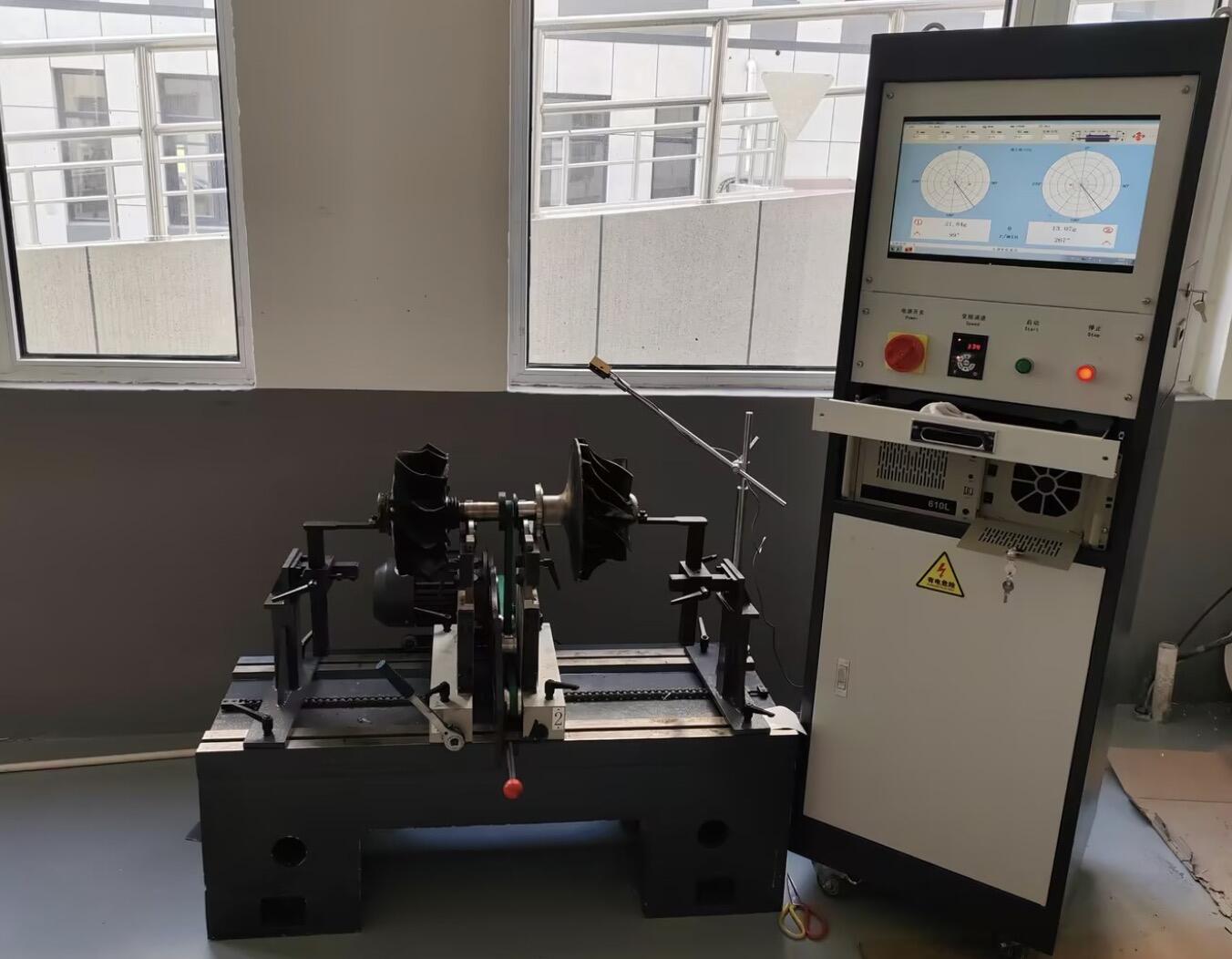

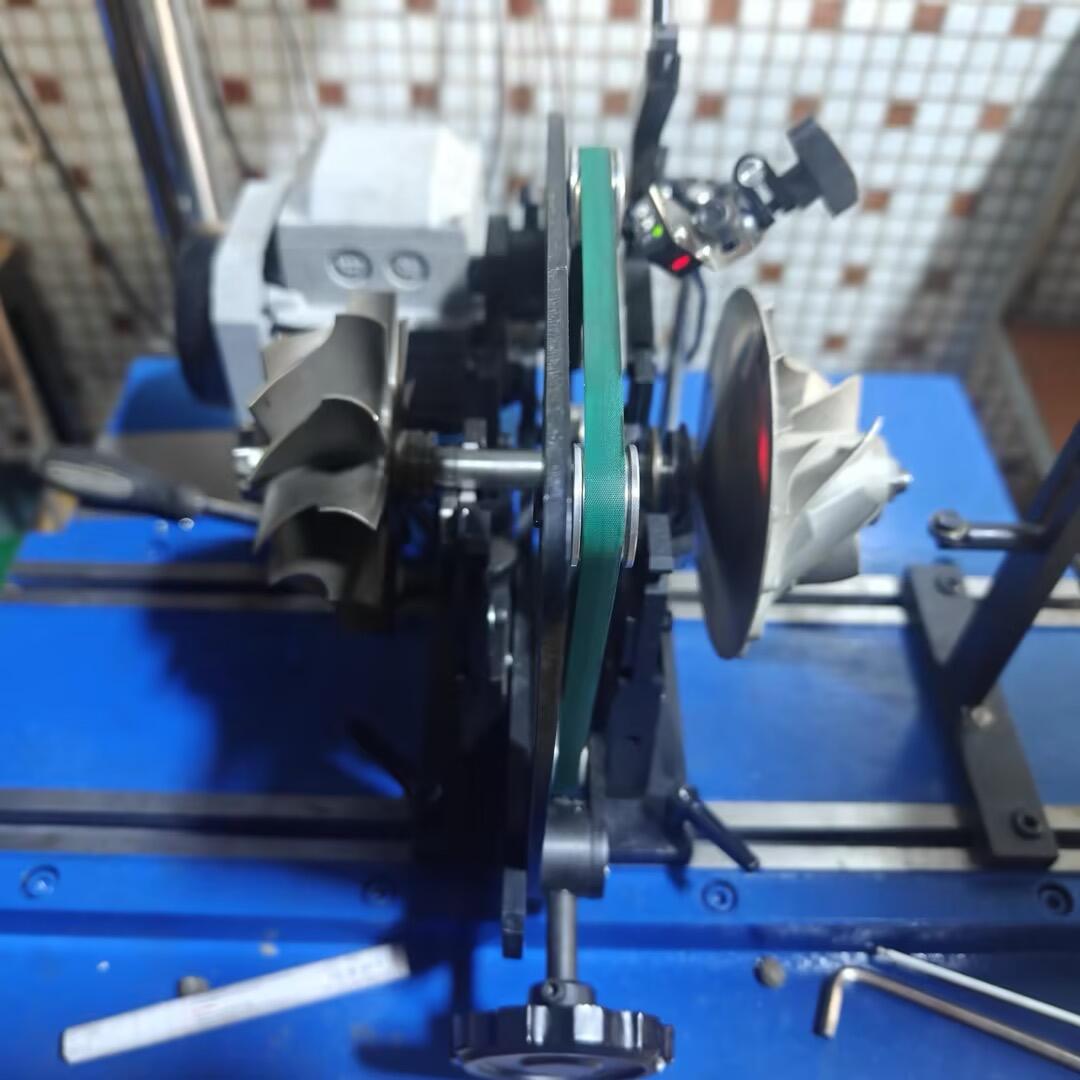

turbocharger balancing machines

Turbocharger balancing machines represent cutting-edge technology in precision engineering, designed to ensure optimal performance and longevity of turbocharger components. These sophisticated machines utilize advanced sensors and digital control systems to measure and correct imbalances in rotating turbocharger parts, particularly the shaft and wheels. The primary function involves spinning the turbocharger assembly at high speeds while measuring vibration levels and mass distribution. Modern balancing machines incorporate real-time monitoring capabilities, allowing for immediate detection of irregularities in rotational movement. They can operate at speeds up to 300,000 RPM, enabling accurate testing under conditions that simulate real-world operation. The machines feature automated correction systems that calculate precise material removal points to achieve perfect balance. Applications extend across automotive, aerospace, and industrial sectors, where turbocharger performance is critical. These machines integrate sophisticated software interfaces that provide detailed analysis reports and maintain quality control records. The technology ensures compliance with strict industry standards while maximizing turbocharger efficiency and reliability.