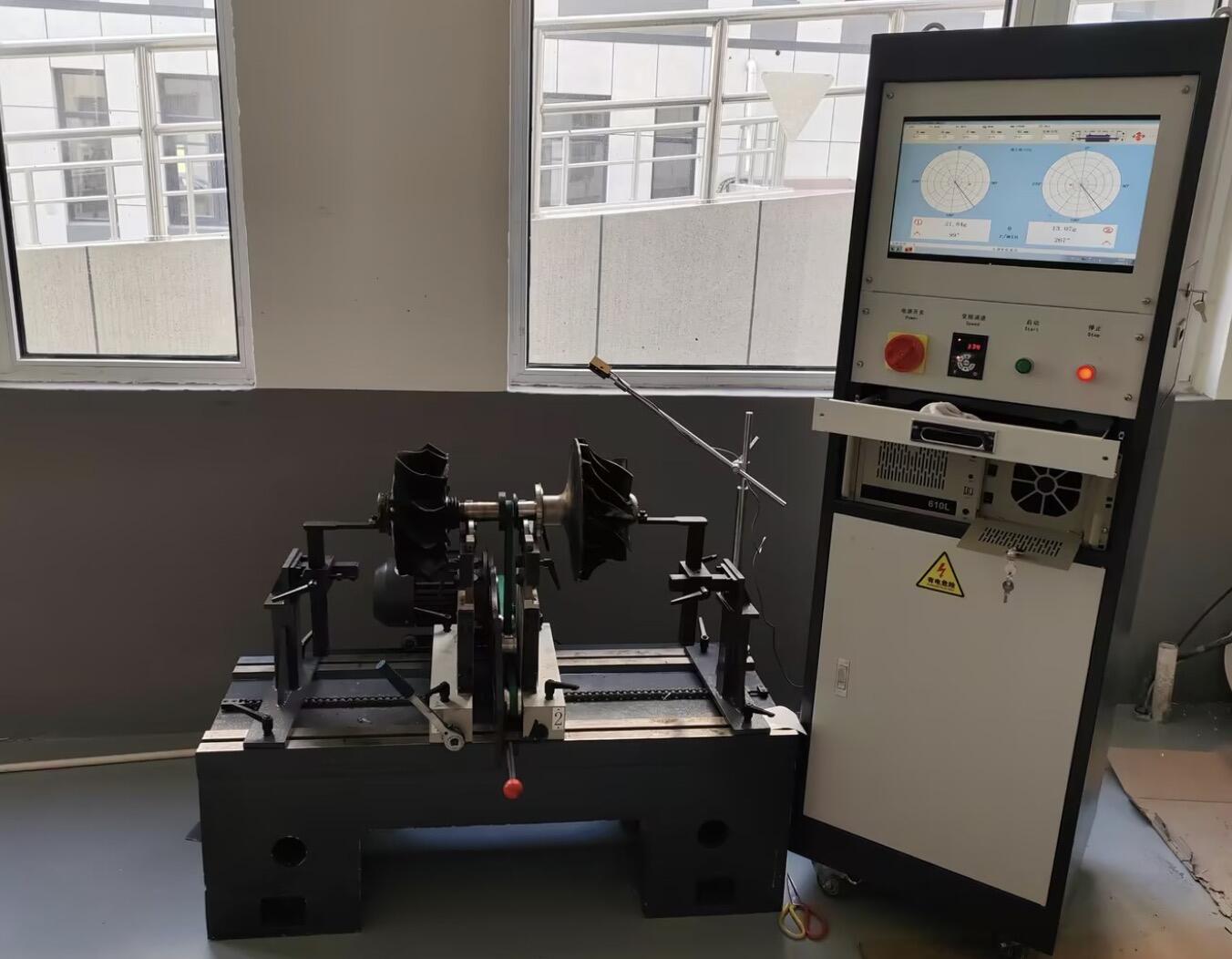

turbocharger belt driven balance machine

The turbocharger belt driven balance machine represents a cutting-edge solution for precise balancing of turbocharger components. This sophisticated equipment utilizes a belt-driven system to rotate turbocharger assemblies at specific speeds, allowing for accurate measurement and correction of imbalances. The machine incorporates advanced sensors and digital measurement technology to detect even minimal vibrations and irregularities in rotating components. Its primary function involves measuring and correcting both single-plane and dual-plane imbalances in turbocharger rotors, ensuring optimal performance and longevity of the final product. The system features automated calibration processes, real-time monitoring capabilities, and precise measurement accuracy down to micron levels. Equipped with user-friendly interface controls, the machine enables operators to easily input parameters, monitor balancing processes, and generate detailed reports. The belt-driven mechanism ensures smooth operation while minimizing wear on components during the balancing process. This technology finds extensive application in automotive manufacturing, turbocharger service centers, and aerospace maintenance facilities, where precision balancing is crucial for component reliability and performance.