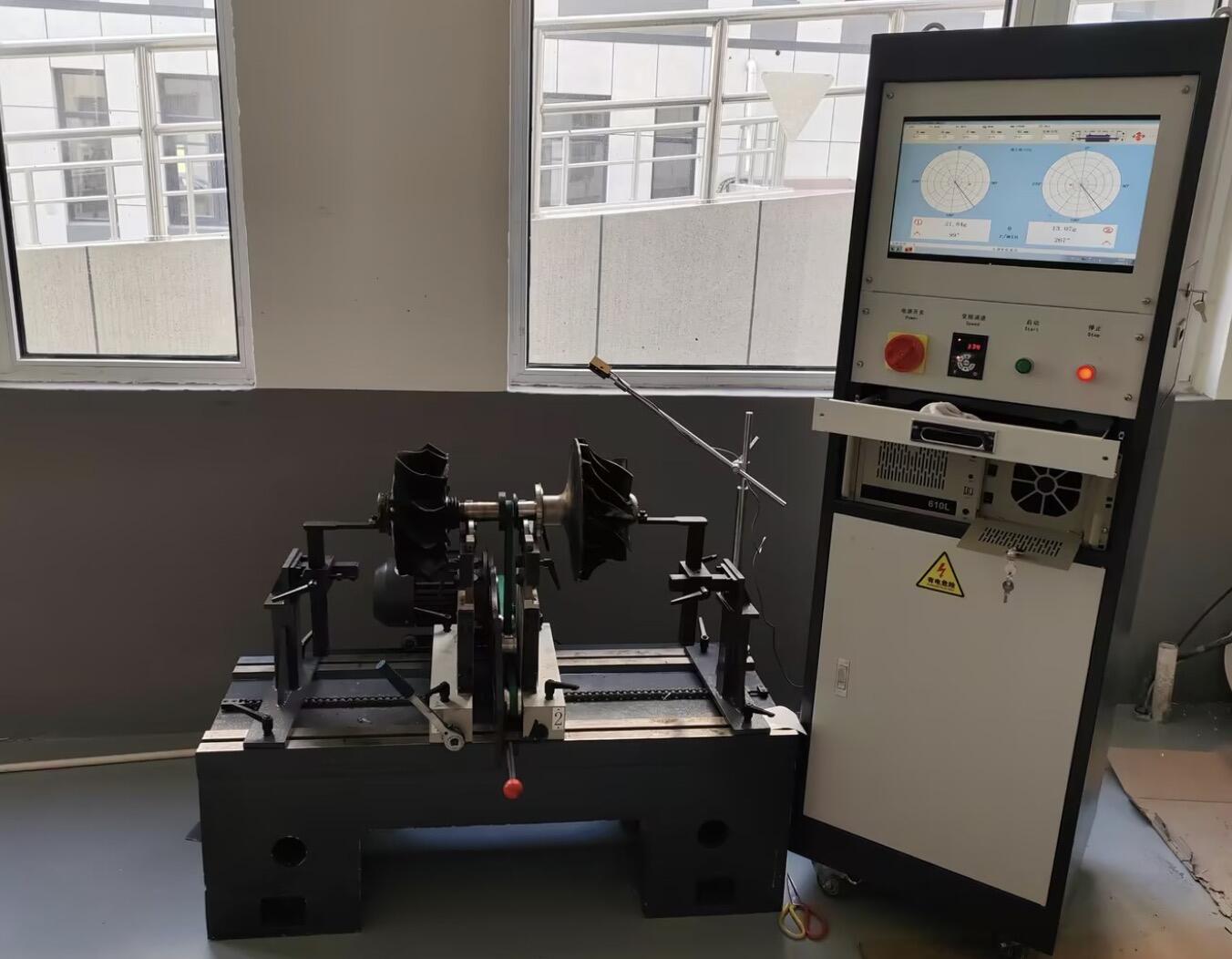

turbocharger belt driven

A belt-driven turbocharger represents an innovative advancement in forced induction technology, combining the benefits of traditional turbocharging with mechanical drive efficiency. This system utilizes a belt connection to the engine's crankshaft, enabling precise control over turbocharger speed and boost pressure. Unlike conventional exhaust-driven turbochargers, the belt-driven system eliminates turbo lag by maintaining consistent boost pressure across all engine speeds. The system comprises a specialized pulley system, high-strength belt, and an advanced bearing assembly that supports high-speed operation. This configuration allows for immediate throttle response and enhanced power delivery, particularly beneficial in low RPM ranges. The technology incorporates sophisticated control mechanisms that adjust boost pressure based on engine load and driving conditions, ensuring optimal performance while maintaining fuel efficiency. Applications range from high-performance passenger vehicles to commercial transport solutions, where consistent power delivery and reliability are paramount. The system's design also includes integrated cooling and lubrication systems, ensuring durability and longevity under demanding operating conditions.