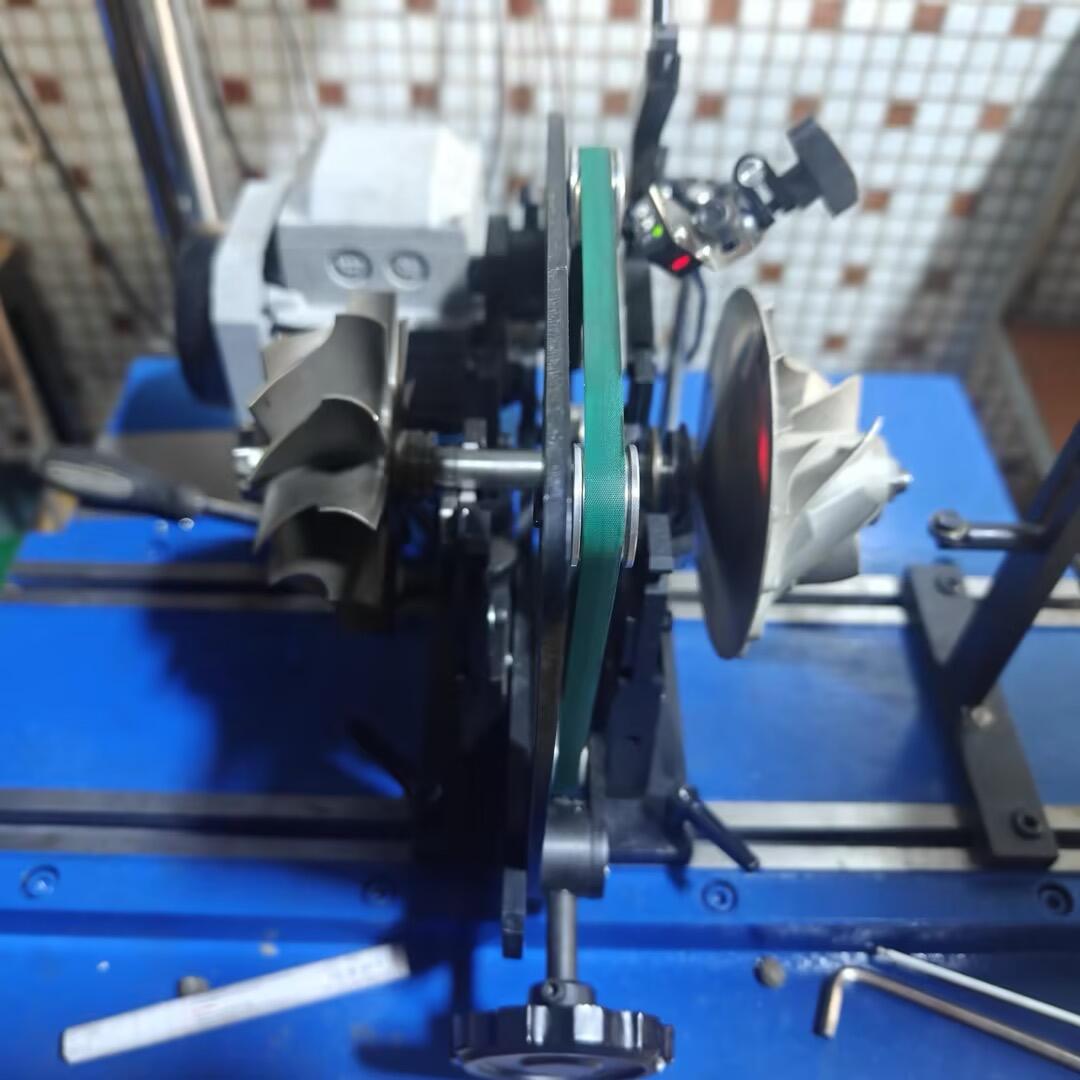

balancing machine for turbochargers

A balancing machine for turbochargers is a sophisticated piece of equipment designed to ensure optimal performance and longevity of turbocharger components. This precision instrument measures and corrects imbalances in both the turbine and compressor wheels, which rotate at extremely high speeds during operation. The machine utilizes advanced sensors and computer-controlled systems to detect even minute variations in weight distribution, allowing for precise corrections to achieve perfect balance. Operating at test speeds of up to 300,000 RPM, these machines can simulate real-world conditions while maintaining strict safety standards. The technology incorporates dual-plane balancing capabilities, enabling simultaneous correction of both dynamic and static imbalances. Modern balancing machines feature automated measurement systems that can detect imbalances as small as 0.1 gram-millimeters, ensuring exceptional accuracy in the balancing process. These machines are equipped with user-friendly interfaces that display real-time data and provide detailed analysis of measurement results. The system includes specialized fixtures and adapters designed specifically for different turbocharger models, making it versatile enough to handle various sizes and types of turbochargers. Integration with quality control systems allows for comprehensive documentation of balancing procedures, ensuring traceability and consistency in manufacturing processes.