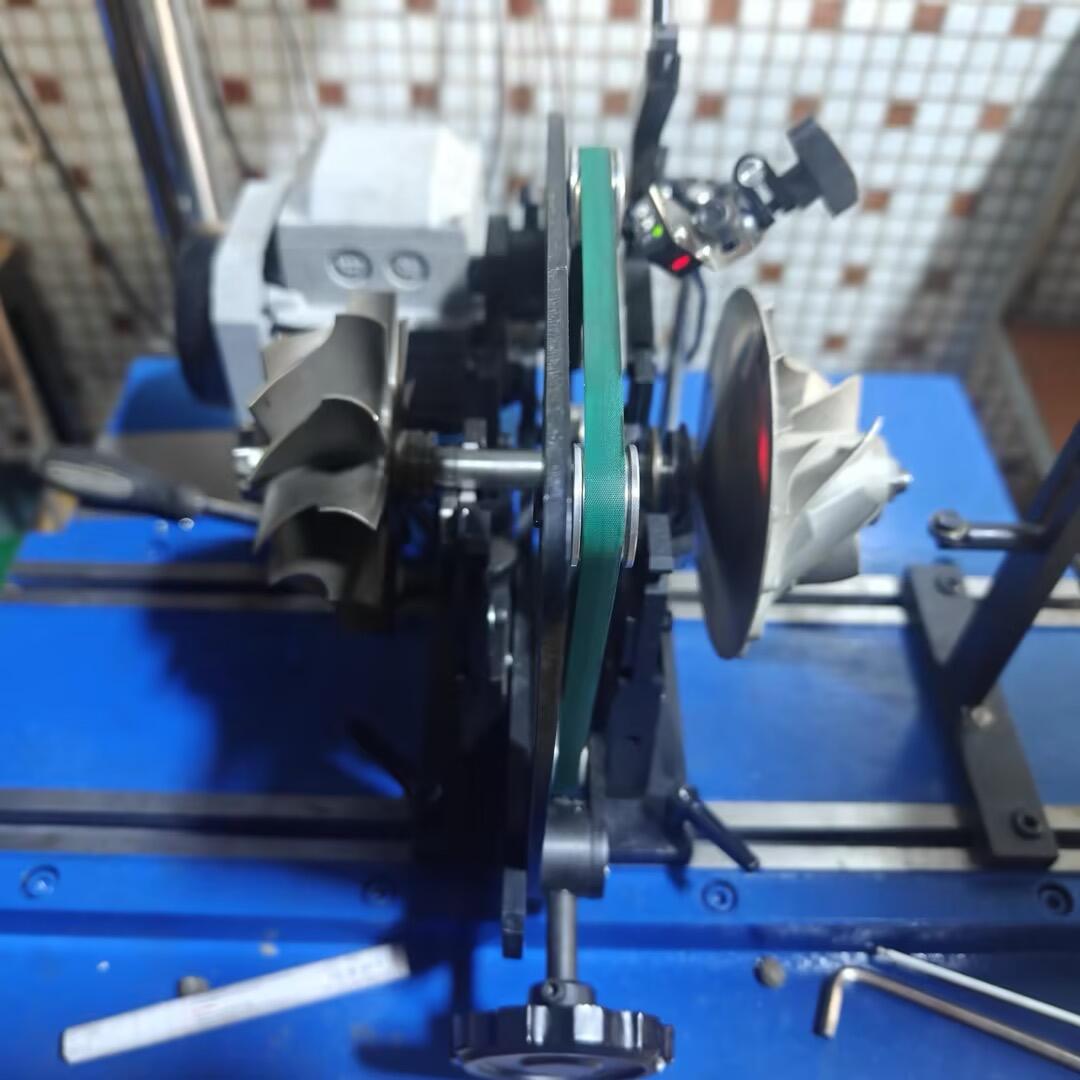

turbine wheel highspeed balancer

The turbine wheel highspeed balancer represents a cutting-edge solution in precision engineering, designed specifically for balancing high-speed rotating components in turbomachinery. This sophisticated equipment utilizes advanced sensor technology and computer-controlled systems to detect and correct even minimal imbalances in turbine wheels, ensuring optimal performance and longevity. The balancer operates by measuring vibration patterns at operational speeds, typically ranging from 3,000 to 300,000 RPM, providing real-time data analysis for precise balance corrections. Its innovative design incorporates vacuum chamber technology, magnetic bearings, and high-precision measurement systems that can detect imbalances down to 0.01 gram-millimeters. The system automatically compensates for environmental factors and maintains consistent measurement accuracy throughout the balancing process. This equipment is essential in various industries, including aerospace, power generation, and automotive manufacturing, where turbine wheel performance directly impacts overall system efficiency and reliability. The balancer's integrated software provides comprehensive reporting and documentation capabilities, ensuring full traceability and quality control compliance.