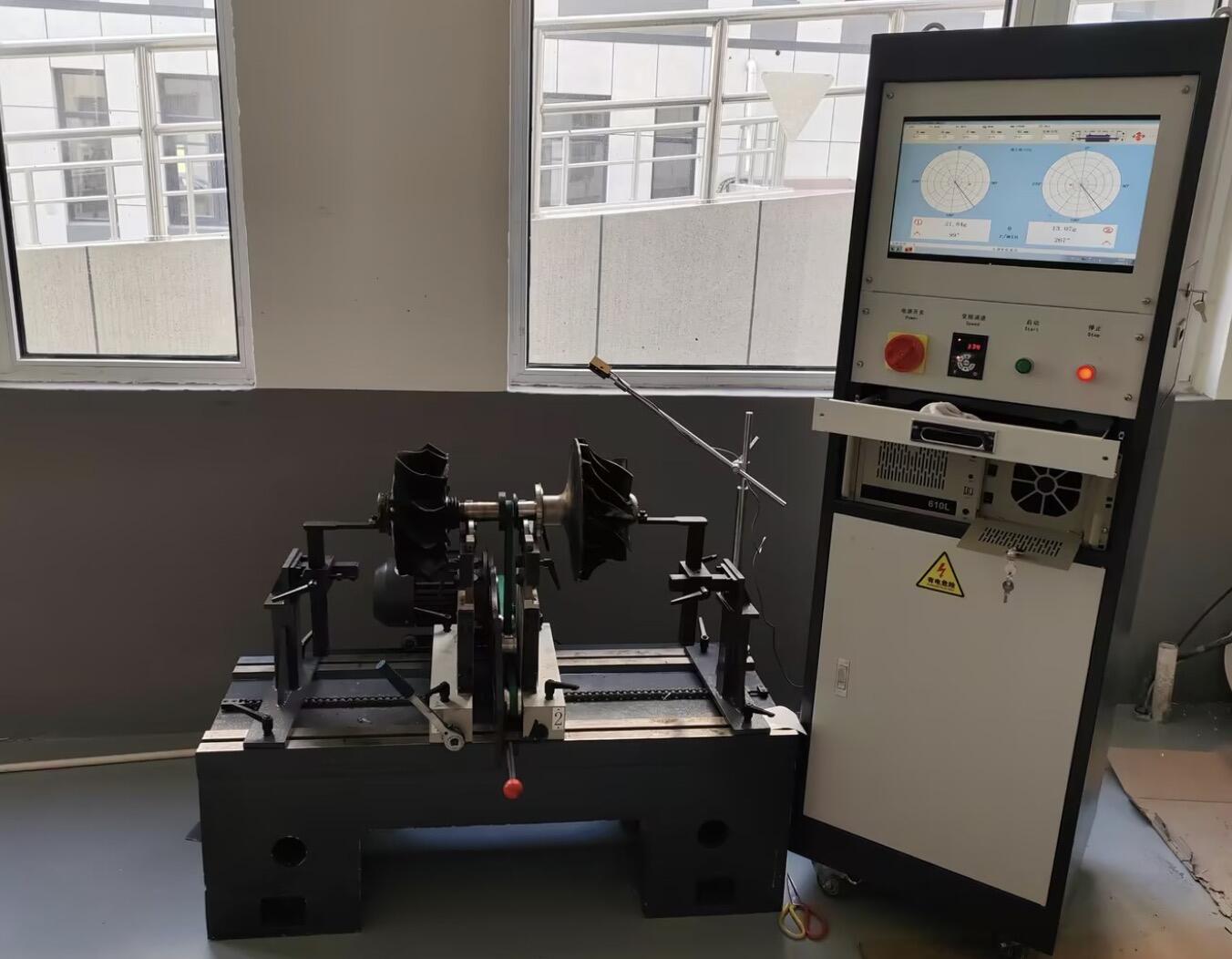

turbocharger core assembly balancing

Turbocharger core assembly balancing is a critical process in the manufacturing and maintenance of turbocharger systems, ensuring optimal performance and longevity of these vital engine components. This precision-driven procedure involves carefully balancing the rotating assembly, which includes the turbine wheel, shaft, and compressor wheel, to minimize vibration and maintain stability at high operational speeds. The process utilizes advanced electronic balancing equipment that can detect even microscopic imbalances in the assembly, which could otherwise lead to decreased performance, increased wear, or catastrophic failure. During the balancing procedure, technicians carefully measure and adjust the weight distribution across the entire rotating assembly, ensuring that the center of mass aligns perfectly with the axis of rotation. This process is performed at multiple speeds to simulate actual operating conditions, typically ranging from 30,000 to over 200,000 RPM. The technology employed includes high-precision sensors, computerized measurement systems, and specialized calibration equipment to achieve the exact specifications required for optimal turbocharger performance.