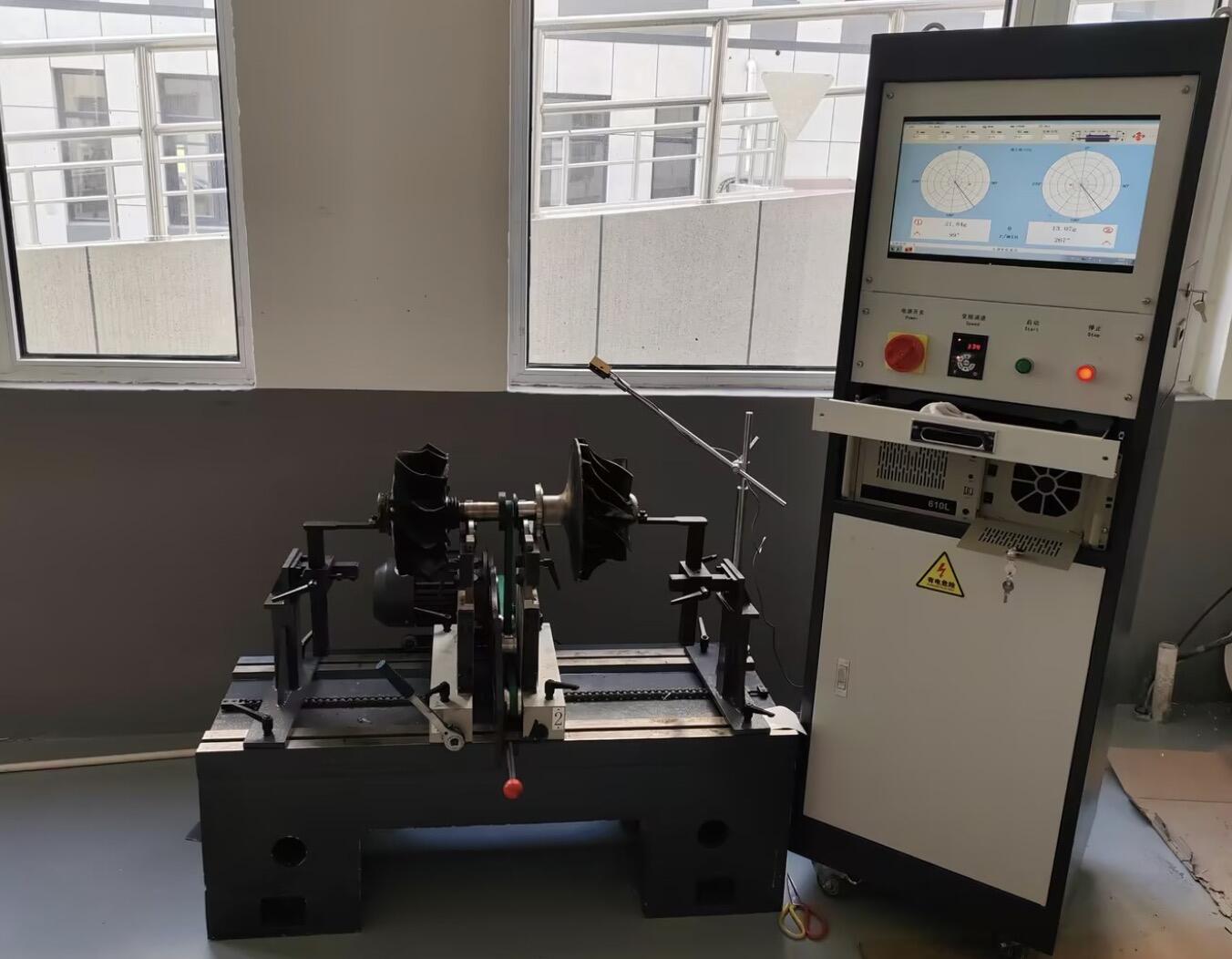

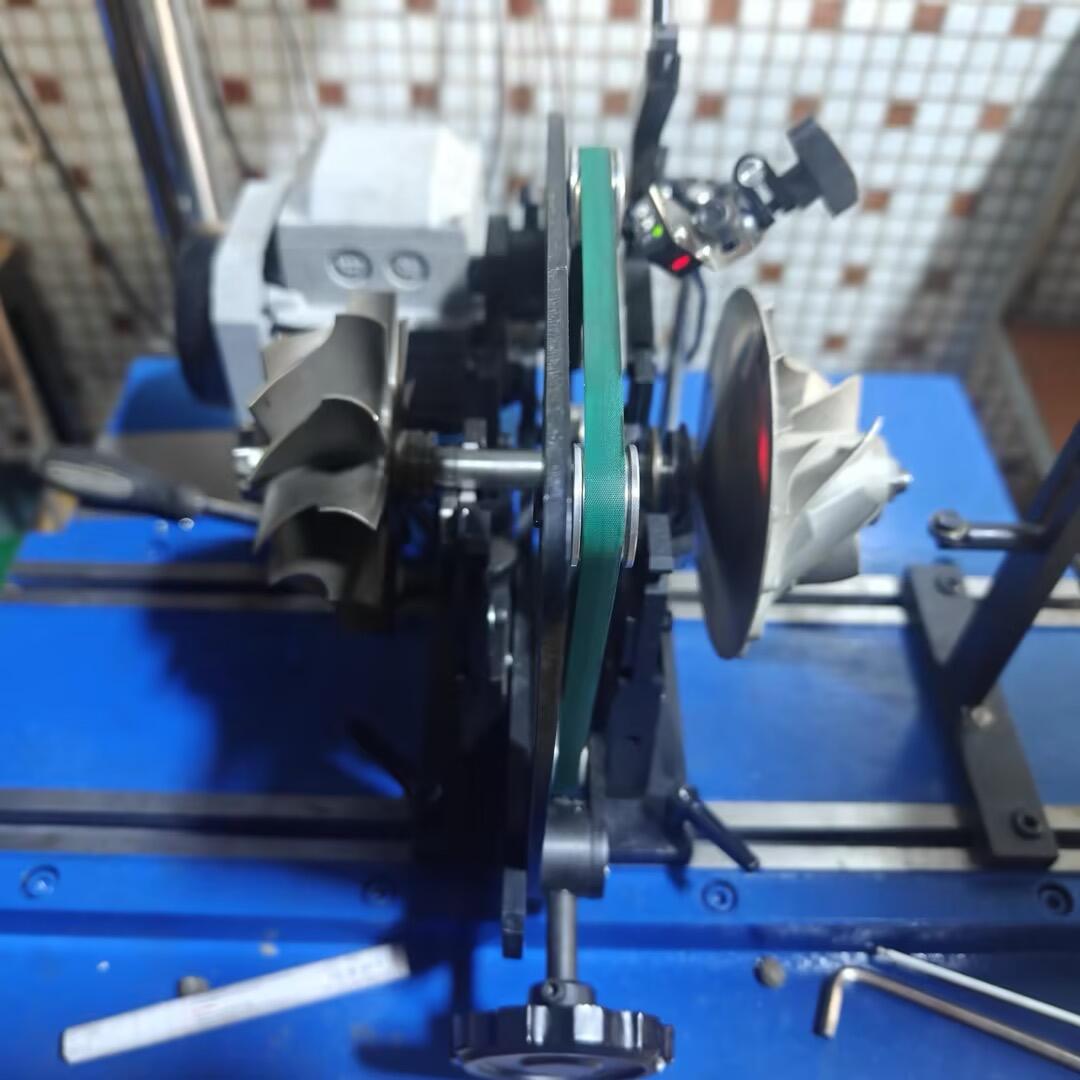

turbocharger balancing machine

A turbocharger balancing machine is a sophisticated piece of equipment designed to ensure optimal performance and longevity of turbocharger components through precise balance measurement and correction. This specialized machine measures and corrects imbalances in both the turbine and compressor wheels, which rotate at extremely high speeds during operation. The machine operates by spinning the components at specific test speeds while using advanced sensors to detect any vibration or imbalance. Through high-precision measurements, it can identify even minimal deviations that could potentially cause performance issues or mechanical failures. The machine incorporates state-of-the-art technology, including digital controls and automated correction systems, to achieve balance tolerances as precise as 0.01 gram-millimeters. It can handle various turbocharger sizes and types, making it essential for both manufacturing and repair operations. The balancing process typically involves multiple steps, including initial measurement, correction weight calculation, and verification runs to ensure proper balance is achieved. Modern turbocharger balancing machines often feature computer-assisted operation, real-time data analysis, and automated report generation capabilities, streamlining the entire balancing process while maintaining exceptional accuracy.