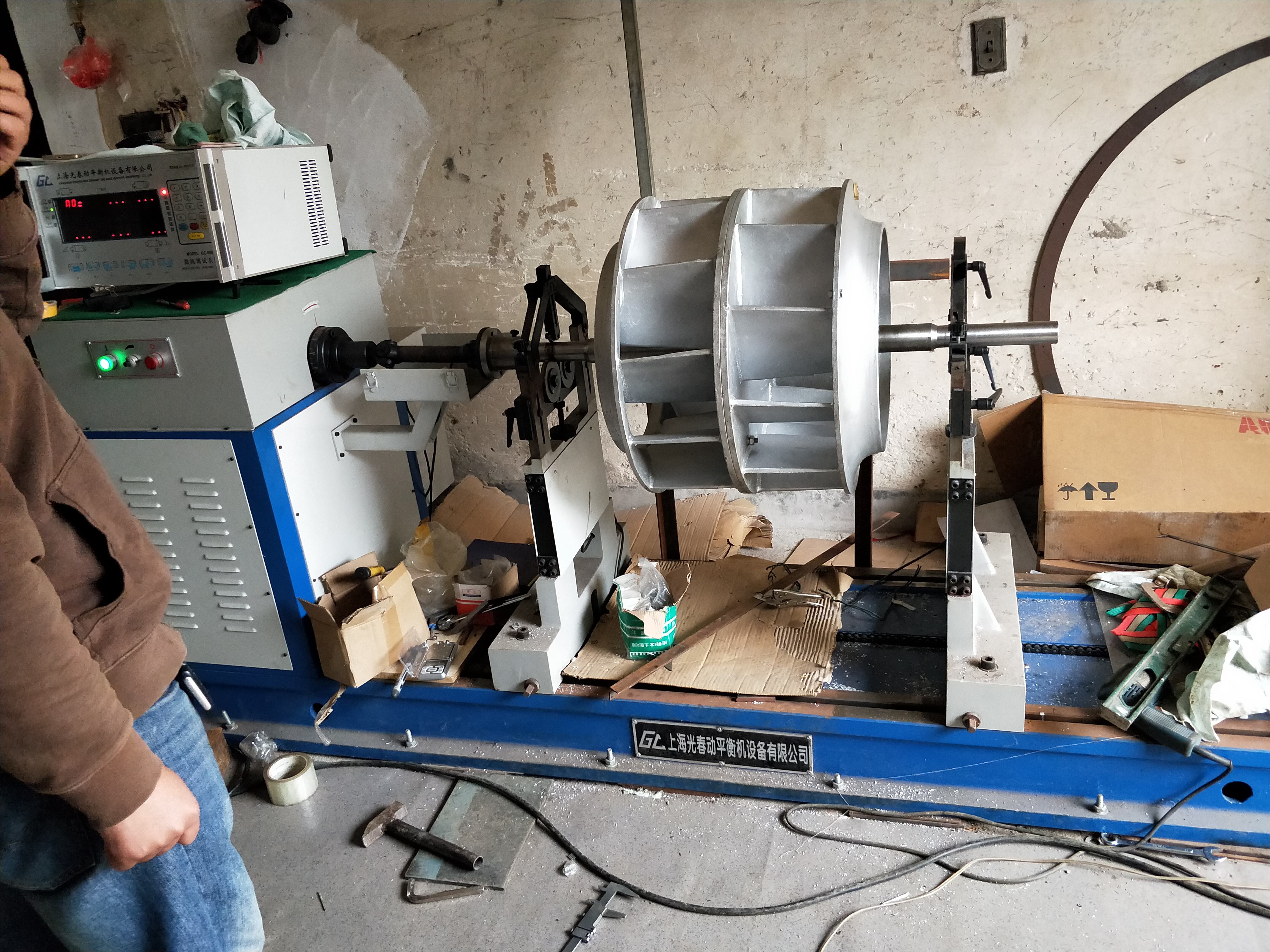

موازنة مروحة العادم

يعتبر موازنة مروحة العادم إجراءً صيانةً حيويًا يضمن الأداء الأمثل وطول عمر أنظمة التهوية. يتضمن هذه العملية التقنية الدقيقة قياس وتدارك أي توزيع غير متوازن للوزن في مكونات المروحة الدوارة، وخاصة مجموعة عجلة المروحة والعمود. أثناء عملية الموازنة، تقوم المعدات المتخصصة بقياس مستويات الاهتزاز في نقاط مختلفة بينما تعمل المروحة بسرعة كاملة. يستخدم الفنيون هذه القياسات لتحديد موقع ودرجة سوء التوازن، ومن ثم يقومون بالتعديلات اللازمة بإضافة أو إزالة الوزن من نقاط محددة على عجلة المروحة. تعتمد موازنة مروحة العادم الحديثة على تقنيات رقمية متطورة، بما في ذلك محللات الاهتزاز وأضواء الوامضة، لتحقيق قياسات دقيقة تصل إلى مستويات الميكرون. عادةً ما تبدأ العملية بفحص دقيق لمجموعة المروحة، تليها عملية تنظيف وتقييم للمكونات الميكانيكية. تتراوح التطبيقات الصناعية من مرافق التصنيع والمطابخ التجارية إلى أنظمة التدفئة والتبريد وتكييف الهواء في المباني الكبيرة. توفر الموازنة المناسبة تقليلًا في استهلاك الطاقة، وتآكل الح bearings وغيرها من المكونات، بالإضافة إلى خفض كبير في مستويات الضجيج. تحتاج هذه الإجراءات الصيانية الأساسية عادةً إلى تنفيذ دوري، اعتمادًا على أنماط الاستخدام والظروف البيئية.