סנכרון ג'ינר ואמזון

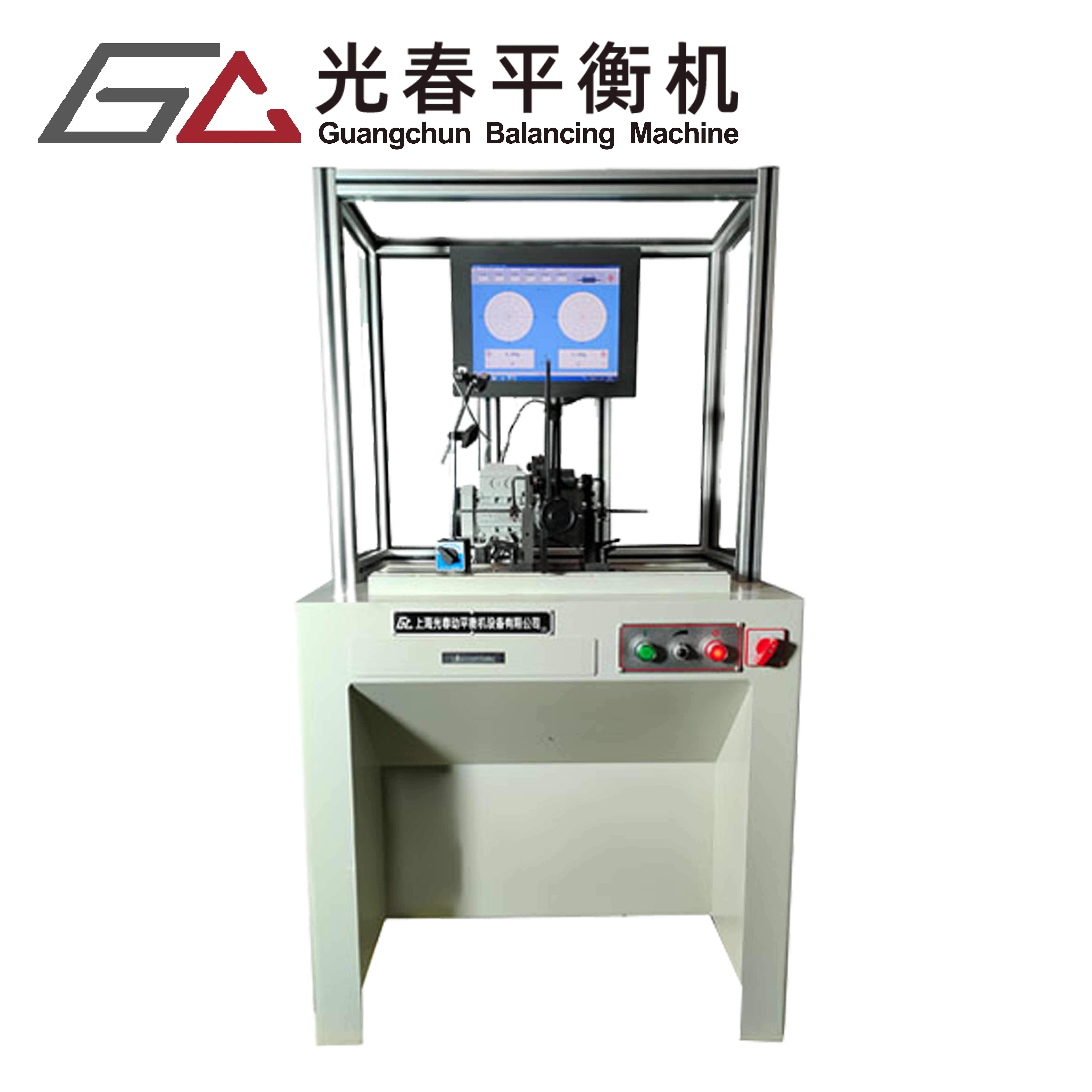

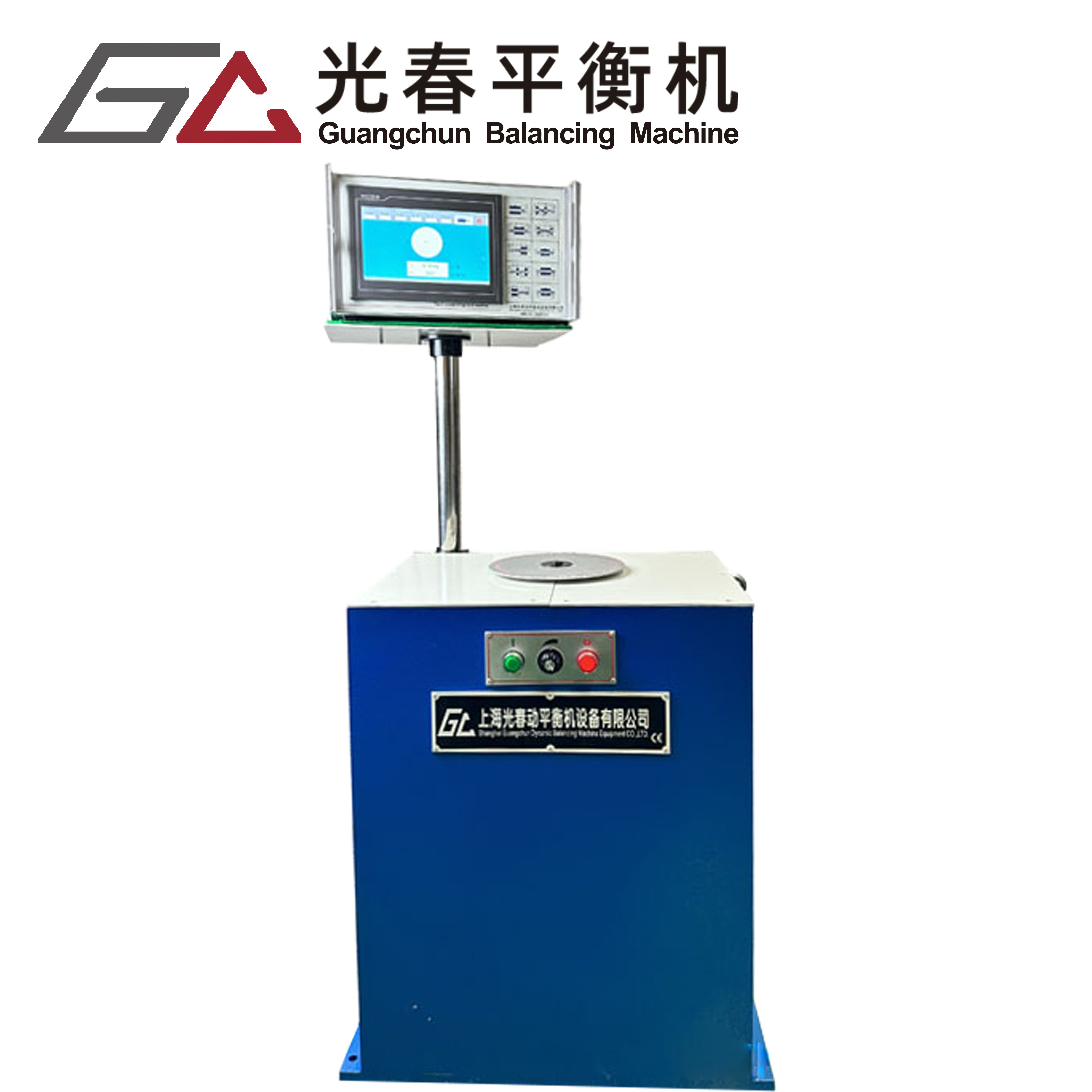

סנפיר גרוס ואיזון הוא תהליך הנדסי מדויק הקריטי לביצועים ואורך חיים אופטימליים של רכיבי מכוניות ומachinery תעשייתית. תהליך sofisticated זה כולל עיבוד Precise של פני השטח של הסנפיר והגדרה מדוקדקת של התפלגות המסה שלו כדי להשיג איזון סיבוב מושלם. התהליך נפתח בבדיקה מקצועית של הסנפיר, ואז מתבצע גרוס Precise באמצעות מכונות CNC מתקדמות לשחזור משטח החיכוך לمواصفות המפעל. תהליך הגרוס מסיר כל אי מושלמות, עיוותים או דפוסי בלאי שצברו לאורך הזמן, ומבטיח משטח שטוח וחלק לחלוטין. לאחר שלב הגרוס, עובר הסנפיר תהליך איזון meticulous באמצעות ציוד אלקטרוני מתקדם לאיזון. הציוד הזה מודד כל אי איזון סיבובי עד חלקים קטנים של אונקיה וקובע בדיוק היכן יש להסיר או להוסיף חומר כדי להשיג איזון אופטימלי. הטכנולוגיה המשמשת בגרוס ואיזון סנפיר משלבת מלאכת יד מסורתית עם דיוק דיגיטלי, תוך שימוש במערכות ממוחשבות שיכולות לאתר ולתקן גם את החריגים הקטנים ביותר. תהליך זה חיוני לשמירה על ביצועי המנוע, הפחתת וויברציה, ומבטיח העברת כוח חלקה באפליקציות שונות, מהמנועי רכב ועד למachinery תעשייתית.