איזון מנעננת באיכות גבוהה

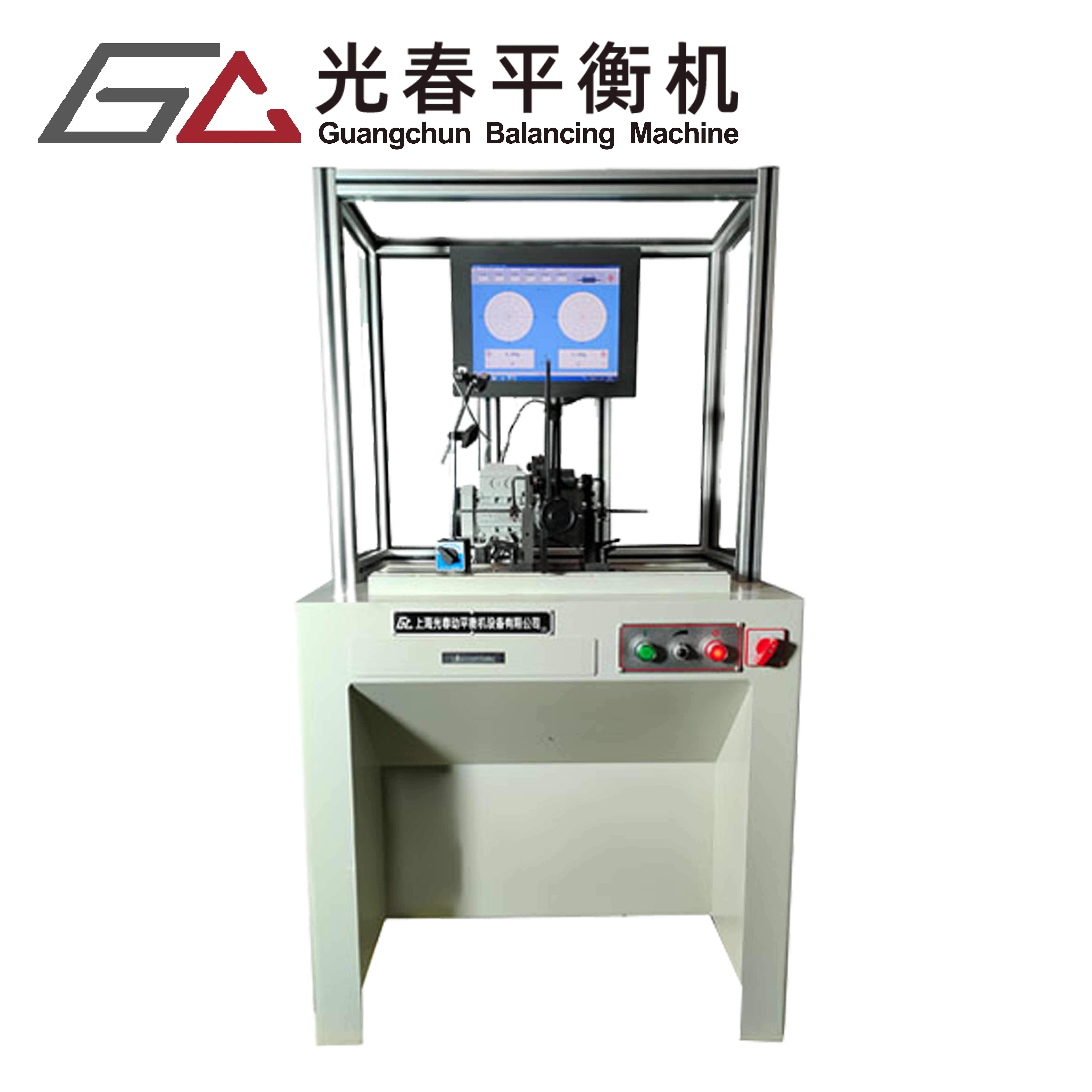

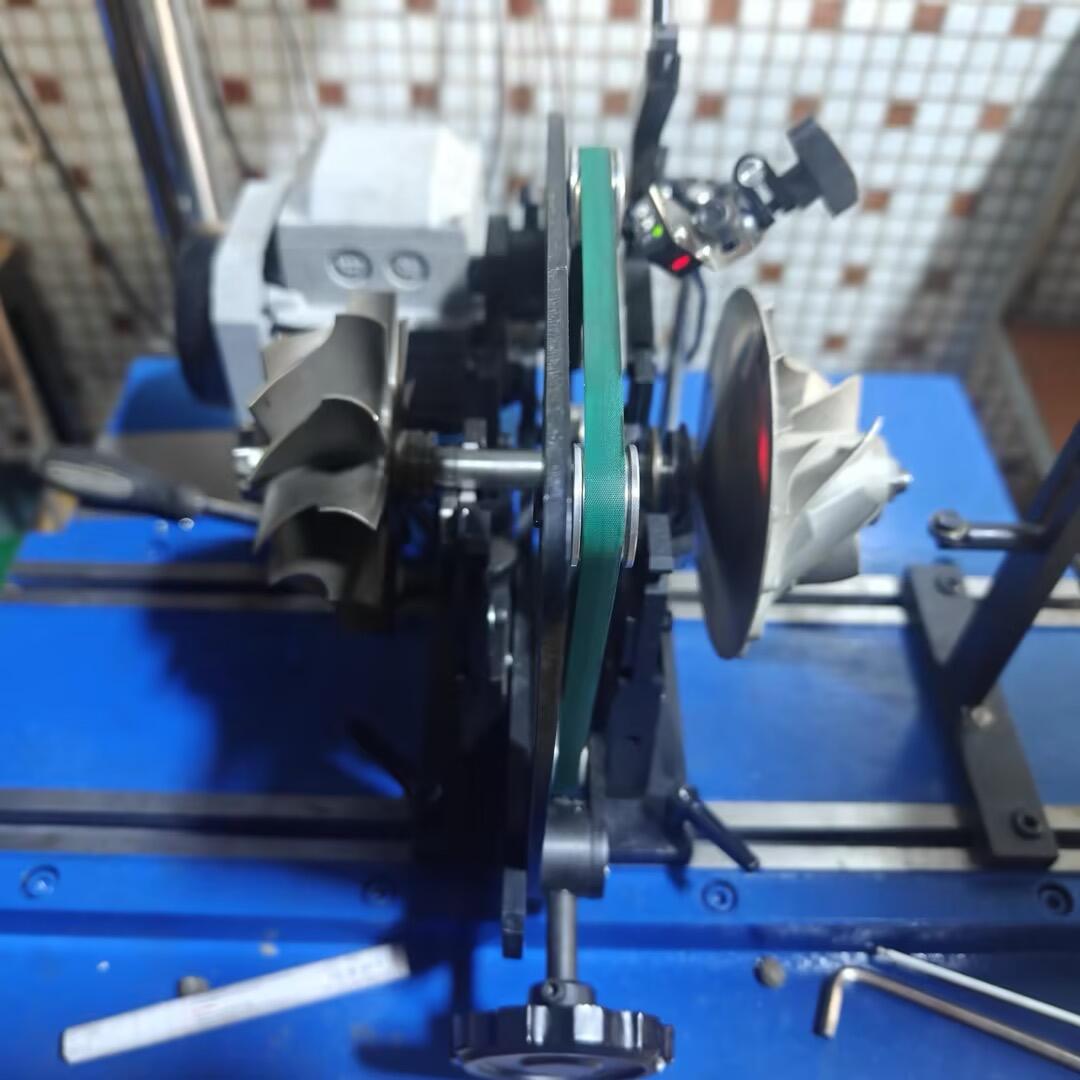

איזון מנעננים באיכות גבוהה מייצג תהליך קריטי ביישומים תעשייתיים ומסחריים מודרניים, ומבטיח ביצועים אופטימליים ואריכות חיים של ציוד סיבובי. הליך המורכב זה עושה שימוש בפתרונות טכנולוגיים מתקדמים כדי למדוד, לנתח ולתקן כל אי-איזון במערכות המנעננים, החל מיחידות קירור קטנות ועד מערכות אוורור תעשייניות גדולות. ההליך כולל ציוד מדידה מדויק שמסוגל לזהות גם רעידות והסטה מזעריות, ומאפשר טכנאיים לזהות את נקודות האי-איזון המדויקות. באמצעות מערכות איזון ממוחשבות, טכנאיים יכולים להשיג דיוק יוצא דופן בプレיסמנט ובتوزيع המשקלים, מה שמוביל להרמוניה סיבובית כמעט מושלמת. הטכנולוגיה כוללת יכולות של פיקוח בזמן אמת, ומאפשרת הערכה רציפה של ביצועי המנגן והתגלה מיידית של כל בעיה שהתפתחה. היישומים משתרעים על פני מגוון ענפי תעשייה, בהם מערכות קירור וחימום (HVAC), עיבוד תעשייני, תשתיות ייצור חשמל, ואוורור בבניינים מסחריים. הליך זה לא רק מאריך את חיי השירות של הציוד אלא גם ממקסם את היעילות האנרגטית, מקטין את עלויות התפעול, ומבטיח פעולה שקתה. ציוד איזון מודרני ליכול להתמודד עם מגוון גדלים וסוגים של מנעננים, החל ממנועים קטנים ומדויקים המשמשים באלקטרוניקה ועד מנורי תעשייה עצומים, מה שהופך אותו לשירות חיוני לשמירה על ביצועים אופטימליים של ציוד בתעשייה.